My stirling engine project

Re: My stirling engine project

You could draw the motor with a pencil, using a T square, set squares, compass, on a drawing board. It's the old fashioned way, but the program is simple, and free, or you just get a bit of paper and a pen or pencil, and make a sketch, it gives you some idea of what your thinking about. "Fraid I'm yet to get into CAD, most of my motors just happen, I collect bits here and there, and when I have a big enough collection, I put all the bits out and see which goes with what, then start modifying parts to fit, its called the cheap way of doing it, very little costs anything. Ian S C

Re: My stirling engine project

Hi jorgealdobr,

If you can't use windows print-screen functions-

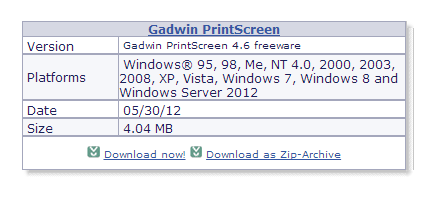

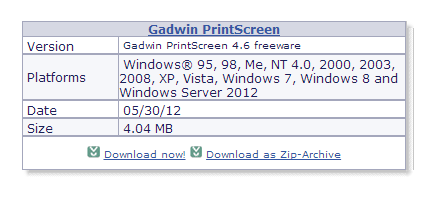

Then here's some freeware/software that i use to capture screenshots. I've been using it for many years, for many situations, without fail.

You can choose multiple capture size/options, file types, file destinations, hot keys, cropping etc.

It's called Gadwin Printscreen..

http://www.gadwin.com/download/

When you open the link, this is the particular software/freeware download box to choose from.

(The program dates are more recent though..)

It's at the bottom of the website page.

I highly recommend it!

It just takes a photograph of the computer screen, except you don't need a camera..

The images you see were made using Gadwin Printscreen, i have used it for many images on this forum (plus photobucket to host them, 'also free').

vamoose

If you can't use windows print-screen functions-

Then here's some freeware/software that i use to capture screenshots. I've been using it for many years, for many situations, without fail.

You can choose multiple capture size/options, file types, file destinations, hot keys, cropping etc.

It's called Gadwin Printscreen..

http://www.gadwin.com/download/

When you open the link, this is the particular software/freeware download box to choose from.

(The program dates are more recent though..)

It's at the bottom of the website page.

I highly recommend it!

It just takes a photograph of the computer screen, except you don't need a camera..

The images you see were made using Gadwin Printscreen, i have used it for many images on this forum (plus photobucket to host them, 'also free').

vamoose

-

jorgealdobr

- Posts: 10

- Joined: Wed Jan 08, 2014 3:55 pm

Re: My stirling engine project

I've found out that dropbox can make printscreens go to the web automagically...

The results are in my gallery :

http://stirlingengineforum.com/gallery/ ... lbum_id=35

Orange things are made of bronze (two kinds : the cylinder cups are pure bronze with a high enough melting point and the piston rings are made of a bronze-graphite alloy that i believe has low friction on steel or aluminum). Bronze alone has a low friction coefficient against steel, bronze-graphite should have even less.

Whitish/grey things are aluminium or steel.

The engine still has heylandt crowns on both pistons as i thought this would increase the surface area of the heat exchangers.

On the cold side i will wound a copper coil to circulate water

On the hot side i will mount a furnace with heat comming from a babington burner in order to burn waste oil or whatever oil comes cheaper.

The two holes (with smaller holes around) are the place where the tubes connecting each cylinder to the regenerator should be placed. I still need to draw the regenerator + tubing.

The engine crankcase is not airtight yet, i have to resize the flyweel - to fit - and enclose the bearings in yet another box, i might as well compensate the smaller flyweel by using two flyweels on each side.

I cant post the burner because its where my innovation lies.

The results are in my gallery :

http://stirlingengineforum.com/gallery/ ... lbum_id=35

Orange things are made of bronze (two kinds : the cylinder cups are pure bronze with a high enough melting point and the piston rings are made of a bronze-graphite alloy that i believe has low friction on steel or aluminum). Bronze alone has a low friction coefficient against steel, bronze-graphite should have even less.

Whitish/grey things are aluminium or steel.

The engine still has heylandt crowns on both pistons as i thought this would increase the surface area of the heat exchangers.

On the cold side i will wound a copper coil to circulate water

On the hot side i will mount a furnace with heat comming from a babington burner in order to burn waste oil or whatever oil comes cheaper.

The two holes (with smaller holes around) are the place where the tubes connecting each cylinder to the regenerator should be placed. I still need to draw the regenerator + tubing.

The engine crankcase is not airtight yet, i have to resize the flyweel - to fit - and enclose the bearings in yet another box, i might as well compensate the smaller flyweel by using two flyweels on each side.

I cant post the burner because its where my innovation lies.

Re: My stirling engine project

I would still recommend that the Heylandt Crown on the cold piston is not required.

Thanks for the photos, just waiting for some photos of your motor in metal. Ian S C

Thanks for the photos, just waiting for some photos of your motor in metal. Ian S C

-

jorgealdobr

- Posts: 10

- Joined: Wed Jan 08, 2014 3:55 pm

Re: My stirling engine project

Even if not required, would it make the engine worse ?

Its very convenient to wrap a coil around it...

Its very convenient to wrap a coil around it...

Re: My stirling engine project

It will create more dead space. That will decrease power.

Re: My stirling engine project

The removal would reduce the moving weight by quite a bit. Make a new cylinder head from aluminium, it could be made from quite a thick bit of metal, and finned. Ian S C